What is DTG Printing?

What is DTG Printing?

As the demand for personalized apparel continues to grow, advancements in printing technology have created new opportunities for customization. DTG Printing (Direct-to-Garment Printing) has become a popular solution, offering flexibility and high-quality output. In this article, we’ll explore DTG printing in-depth, including its definition, process, costs, comparison with traditional printing methods, and practical applications in the apparel industry.

What is DTG Printing?

DTG printing, which directly prints onto clothing, is one of the most advanced printing methods currently available. It is similar to an inkjet printer in the office, but the medium is fabric rather than paper, and it uses specialized water-based or plant-based ink. This technology uses inkjet printers to directly print designs onto clothing without the need for plate making, with high flexibility and immediacy.

Key Features of DTG Printing

· No need for plates or screens: Designs are printed directly from digital files.

· Supports intricate designs: Ideal for high-resolution images, gradients, and complex patterns.

· Eco-friendly inks: Uses water-based inks, making it an environmentally friendly option.

· Fabric compatibility: Works best on natural fibers like cotton and bamboo.

Ideal Scenarios for DTG Printing

DTG printing is well-suited for small-batch orders and personalized products, such as custom t-shirts, event apparel, and limited-edition designs.

In summary: DTG printing is a sustainable, high-quality digital printing solution perfect for brands seeking flexibility and creative freedom.

How Does DTG Printing Work?

The DTG printing process involves several precise steps:

1. Garment Pre-Treatment

A pre-treatment solution is applied to the garment to ensure the ink adheres properly to the fabric and to enhance color vibrancy. The garment is then heat-pressed to dry the solution.

2. Design Printing

Using a DTG printer, the design is printed directly onto the pre-treated garment. The inkjet technology accurately sprays ink into the fibers for a sharp and vibrant result.

3. Curing the Ink

After printing, the garment undergoes heat curing via a heat press or dryer to lock the ink into the fabric.

4. Quality Inspection

The final product is inspected for color accuracy, print clarity, and positioning.

Total Time:

From pre-treatment to final curing, the process typically takes 15-20 minutes per garment.

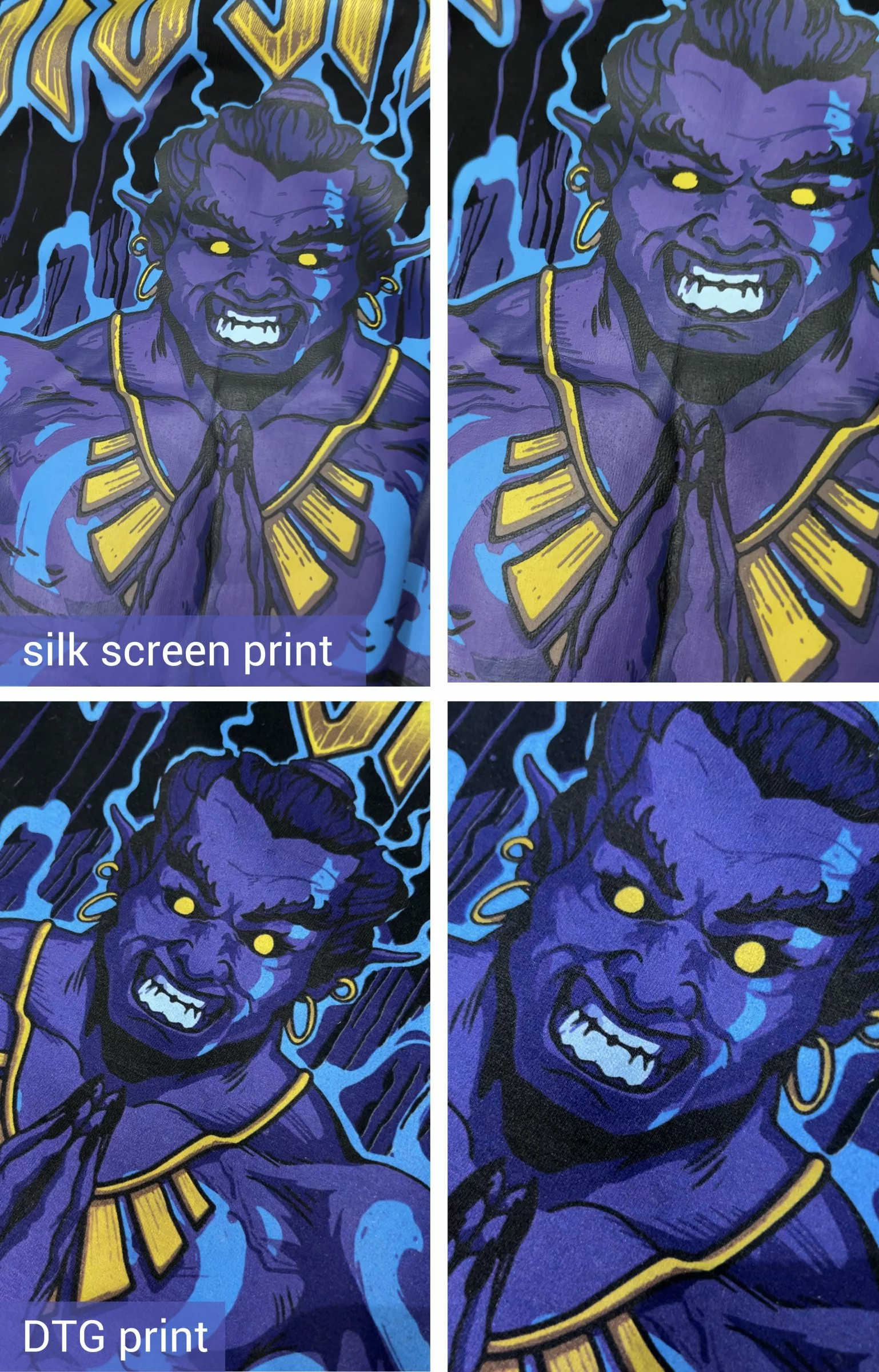

DTG Printing vs. Traditional Screen Printing

The differences between DTG printing and traditional screen printing highlight their unique strengths and use cases.

|

Comparison Criteria

|

DTG Printing

|

Traditional Screen Printing

|

|

Order Size

|

Ideal for small-batch or one-off orders

|

Best for large-scale production

|

|

Design Complexity

|

Supports full-color, intricate designs (e.g., gradients, photos)

|

Limited to simple designs with fewer colors

|

|

Cost Structure

|

Higher cost per unit, but no setup fees

|

Lower cost per unit, but requires high initial setup costs

|

Fabric Compatibility | Best for natural fibers like cotton | Suitable for a wide range of fabrics, including synthetics |

Environmental Impact | Uses eco-friendly water-based inks | May involve solvent-based inks, less eco-friendly |

Summary: DTG printing is ideal for flexibility, low-volume orders, and complex designs, while screen printing is better suited for large-scale production at lower costs.

Cost Analysis of DTG Printing

The cost of DTG printing depends on several factors:

1. Equipment Costs

DTG printers are a significant investment, often priced between $20,000 and $50,000.

2. Ink Costs

Water-based DTG inks are more expensive than traditional inks. Ink consumption increases with larger or more intricate designs.

3. Pre-Treatment Costs

Includes the cost of pre-treatment solution and additional drying equipment.

4. Labor Costs

Labor is required for pre-treatment, printing, and curing the garments.

5. Estimated Cost Per Garment

Printing one t-shirt typically costs between $5 and $10, depending on the design complexity and fabric type.

Applications of DTG Printing in Apparel Products

The emergence of DTG printing technology has provided apparel brands with unprecedented opportunities for personalized customization. Whether it's t-shirts, hoodies, activewear, or custom gifts like pillows and canvas bags, DTG printing makes it all easily achievable. Brands can leverage this technology to offer consumers unique customization experiences, catering to their demand for personalized products.

In particular, when it comes to DTG printing hoodies, brands can create designs that showcase their unique identity and print them directly onto hoodies. This not only maintains the comfort and durability of the apparel but also enhances brand recognition.

DTG printing is ideal for the following products and scenarios:

T-Shirts and Hoodies

· Cotton t-shirts and hoodies are the most common applications, perfect for intricate, multi-color designs.

· Highly favored by personalized brands and streetwear labels.

Custom Gifts

· Small-batch custom apparel, such as commemorative clothing for family gatherings or corporate events.

Creative Apparel

· Suitable for artists and designers to release exclusive designs for limited-edition collections.

How Long Does It Take to Print One Garment?

The time required for DTG printing varies based on the complexity of the design and the garment size:

· Simple Designs: 3-5 minutes.

· Complex Full-Color Designs: 8-10 minutes.

· Pre-Treatment and Curing: An additional 5-10 minutes.

Average Total Time: 15-20 minutes per garment.

Durability of DTG Printing: How Long Does It Last?

DTG prints are highly durable and typically last as long as the garment itself, provided proper care is taken. Factors affecting durability include:

1. Fabric Quality

Natural fibers like cotton hold ink better and provide longer-lasting results.

2. Proper Washing Techniques

Wash garments inside out to protect the print.

Use cold water and mild detergents.

Avoid bleach or strong cleaning agents.

3. Drying Methods

Air drying is preferred to maintain print quality.

If using a dryer, opt for a low-heat setting.

How to Wash DTG-Printed Garments?

To maximize the longevity of DTG prints, follow these washing guidelines:

1. Turn the Garment Inside Out

Reduces friction and protects the print.

2. Use Cold Water and Gentle Detergents

Avoid hot water, which can weaken the ink's bond to the fabric.

3. Gentle Washing Cycle

Select a delicate or low-spin setting.

4. Air Dry When Possible

Minimize exposure to high heat by air drying or using a low-heat tumble dry setting.

Conclusion

DTG printing is a flexible, eco-friendly, and high-quality printing method that is ideal for custom, small-batch production and intricate designs. While the cost may be higher compared to traditional methods, its ability to deliver stunning, detailed prints makes it a valuable tool for brands seeking to stand out in a competitive market.

Whether you’re producing personalized t-shirts, exclusive hoodies, or event merchandise, DTG printing provides unmatched quality and creative freedom. By following proper washing and care instructions, DTG-printed garments can maintain their vibrant appearance for years to come. is a flexible, eco-friendly, and high-quality printing method that is ideal for custom, small-batch production and intricate designs. While the cost may be higher compared to traditional methods, its ability to deliver stunning, detailed prints makes it a valuable tool for brands seeking to stand out in a competitive market.

Wetowear is equipped to deliver exceptional DTG printing services that meet your quality and customization needs.

For more information on how we can help you with your DTG printing needs, visit Wetowear.