What Is Silk Screen Printing?

What Is Silk Screen Printing? A Comprehensive Guide for Clothing Brand Merchants

As a clothing brand merchant, you're constantly seeking ways to make your products stand out in a competitive market. Enter silk screen printing — a time-tested method for creating durable, bold, and eye-catching designs. This guide explores the process, benefits, and practical applications of silk screen printing, tailored specifically for clothing brands like yours.

What Is Silk Screen Printing and How Does It Work?

Silk screen printing is a stenciling technique that transfers ink through a porous mesh screen onto a substrate, such as fabric, paper, or plastic. This method allows for bold, vibrant designs that are both durable and visually striking.This method allows for bold, vibrant designs that are both durable and visually striking.

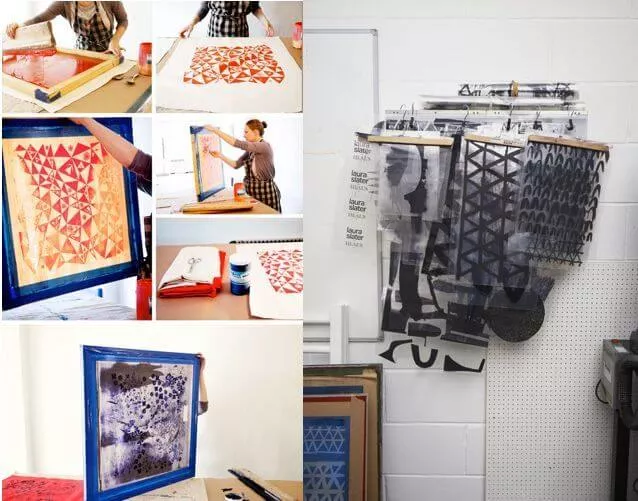

Here’s a quick breakdown of the process:

1. A design is created and translated into a stencil.

2. The stencil is attached to a mesh screen stretched tightly across a frame.

3. Ink is pushed through the open areas of the stencil using a squeegee, transferring the design to the material below.

The method is celebrated for its versatility. Clothing brands frequently use silk screen printing to create customized apparel like t-shirts, hoodies, tote bags, and hats. It’s also a preferred choice for promotional products and event merchandise due to its ability to handle bold graphics and large orders efficiently.

The Step-by-Step Process of Silk Screen Printing

1. Design Creation:

Start with a high-quality design. Simpler graphics with distinct color separations work best for silk screen printing. Digital files are often prepared in vector formats like .AI or .EPS for precision.

2. Screen Preparation:

A fine mesh screen is coated with a light-sensitive emulsion.

The design is transferred onto the emulsion-coated screen using UV light, which hardens the exposed areas, leaving the design open.

3. Material Setup:

The chosen material (e.g., cotton, polyester, or blended fabric) is placed on a flat printing surface.

Proper alignment ensures consistent and professional results.

4. Ink Application:

Ink is poured onto the screen and spread evenly with a squeegee.

Pressure is applied to force the ink through the open areas of the stencil and onto the material.

5. Curing the Print:

Once printed, the material is dried and cured under high heat.

This step ensures that the ink bonds permanently with the material, preventing peeling, cracking, or fading.

6. Cleaning and Recycling Screens:

Screens are cleaned with a solvent to remove the emulsion, making them ready for reuse with different designs.

This reduces waste and makes silk screen printing eco-friendly when done properly.

Advantages and Disadvantages of Silk Screen Printing

Advantages:

1. Unmatched Durability:

The ink penetrates deeply into the fabric, resulting in designs that last through countless washes and wears.

2. Vivid, High-Quality Prints:

Silk screen printing delivers bold, opaque colors that stand out, even on dark fabrics. This makes it ideal for branding purposes.

3. Cost-Efficiency for Bulk Orders:

While the setup process is labor-intensive, the per-unit cost decreases significantly for large print runs, making it a budget-friendly choice for clothing brands producing in bulk.

4. Versatility:

Suitable for various surfaces, including textiles, wood, glass, and metal, allowing brands to experiment with diverse product lines.

Disadvantages:

1. High Setup Costs for Small Runs:

The initial preparation of screens and stencils can make small orders less economical.

2. Limited Color Blending:

Each color requires its own screen, limiting intricate, multicolored designs unless additional resources are allocated.

3. Environmental Concerns:

Without proper disposal of chemicals and inks, the process can have a negative environmental impact. However, many printers now use eco-friendly inks and cleanup solutions.

Silk Screen Printing vs. Other Methods

|

Feature

|

Silk Screen Printing

|

Digital Printing

|

Vinyl Printing

|

|

Durability

|

Extremely durable; lasts for years

|

Good, but less robust

|

High; less prone to cracking

|

|

Cost for Bulk

|

Cost-effective

|

More expensive per unit

|

Affordable for smaller runs

|

|

Color Vibrancy

|

Excellent, especially for bold designs

|

Moderate, may lack vibrancy

|

Good, but limited to solid tones

|

Setup Time | Time-intensive for screen preparation | Minimal | Moderate |

Best For | Bulk orders and bold designs | Small, detailed prints | Custom, short-term prints |

Applications of Silk Screen Printing in the Clothing Industry

For clothing brands, silk screen printing unlocks limitless possibilities. Here are a few practical applications:

· Custom Apparel: Design branded t-shirts, hoodies, or uniforms with company logos or unique artwork.

· Limited-Edition Collections: Create exclusive designs to build hype and foster brand loyalty.

· Event Merchandise: Offer high-quality printed items for corporate events, music festivals, or promotional campaigns.

· Accessories: Diversify your product line with printed tote bags, bandanas, or aprons.

Caring for Silk Screen Prints

To maximize the lifespan of your silk screen-printed items, follow these simple care tips:

1. Wash Inside Out: Protect the print from direct friction in the wash.

2. Use Cold Water: Hot water can weaken the ink bond over time.

3. Avoid Harsh Detergents: Stick to mild detergents to maintain the vibrancy of your designs.

4. Air Dry When Possible: Heat from dryers can degrade the print quality. If using a dryer, opt for a low heat setting.

Why Choose Silk Screen Printing Services?

For clothing brands, partnering with a reputable silk screen printing service ensures:

· Consistency: Professional services maintain quality across large batches, avoiding inconsistencies common with DIY methods.

· Customization: Services often offer a wide range of materials, inks, and finishes to meet your brand’s needs.

· Scalability: From small pilot runs to mass production, silk screen printing services can adapt to your business's growth.

Summary

Silk screen printing remains a cornerstone of high-quality apparel production, offering vibrant, durable, and scalable solutions for clothing brands. Whether you're launching a new product line, creating limited-edition merchandise, or enhancing your brand's visual identity, silk screen printing delivers unmatched results.

Invest in this powerful printing method to transform your designs into wearable art that resonates with your customers. With proper care and strategic use, silk screen printing can become a cornerstone of your brand's success.