Understanding Tri-Blend Fabrics: Why They’re Perfect for Your Clothing Brand

Understanding Tri-Blend Fabrics: Why They’re Perfect for Your Clothing Brand

In the world of textiles and apparel, tri-blend is a term gaining momentum, especially among clothing brand merchants. If you're in the business of creating or selling apparel, understanding what a tri-blend fabric is and why it’s so popular can give you a competitive edge.

This article explores everything you need to know about tri-blend fabrics, from their composition to their advantages and practical applications.

What is a Tri-Blend Fabric?

Tri-blend fabrics are textiles made from a combination of three different fibers: cotton, polyester, and rayon. Each fiber contributes distinct properties to the blend, resulting in a fabric that offers a unique balance of comfort, durability, and style.

· Cotton: Known for its natural softness and breathability, cotton is an essential component of tri-blends. It ensures comfort and a lightweight feel.

· Polyester: This synthetic fiber adds strength, durability, and wrinkle resistance to the fabric. It also helps garments retain their shape after washing.

· Rayon: Originally created as a silk alternative, rayon lends the fabric its smooth texture, drape, and luxurious finish.

When combined, these fibers create a fabric that feels ultra-soft, stretches comfortably, and lasts longer than single-fiber textiles.

Why Are Tri-Blend Fabrics Popular?

1. Superior Comfort:

Tri-blends are prized for their unparalleled softness and light feel. The rayon adds a luxurious touch, while the cotton ensures the fabric is breathable, making it perfect for all-day wear.

2. Durability:

Thanks to polyester, tri-blends are resistant to shrinking and maintain their shape after repeated washes. This durability makes them ideal for activewear, casual apparel, and custom printing.

3. Versatility:

The unique texture and flexibility of tri-blends make them suitable for various clothing types, including T-shirts, dresses, and even sportswear.

4. Premium Look:

Rayon contributes to the fabric's silky finish and enhances its draping qualities, giving garments a high-end look and feel. This feature is especially appealing to merchants targeting a premium market segment.

5. Ideal for Customization:

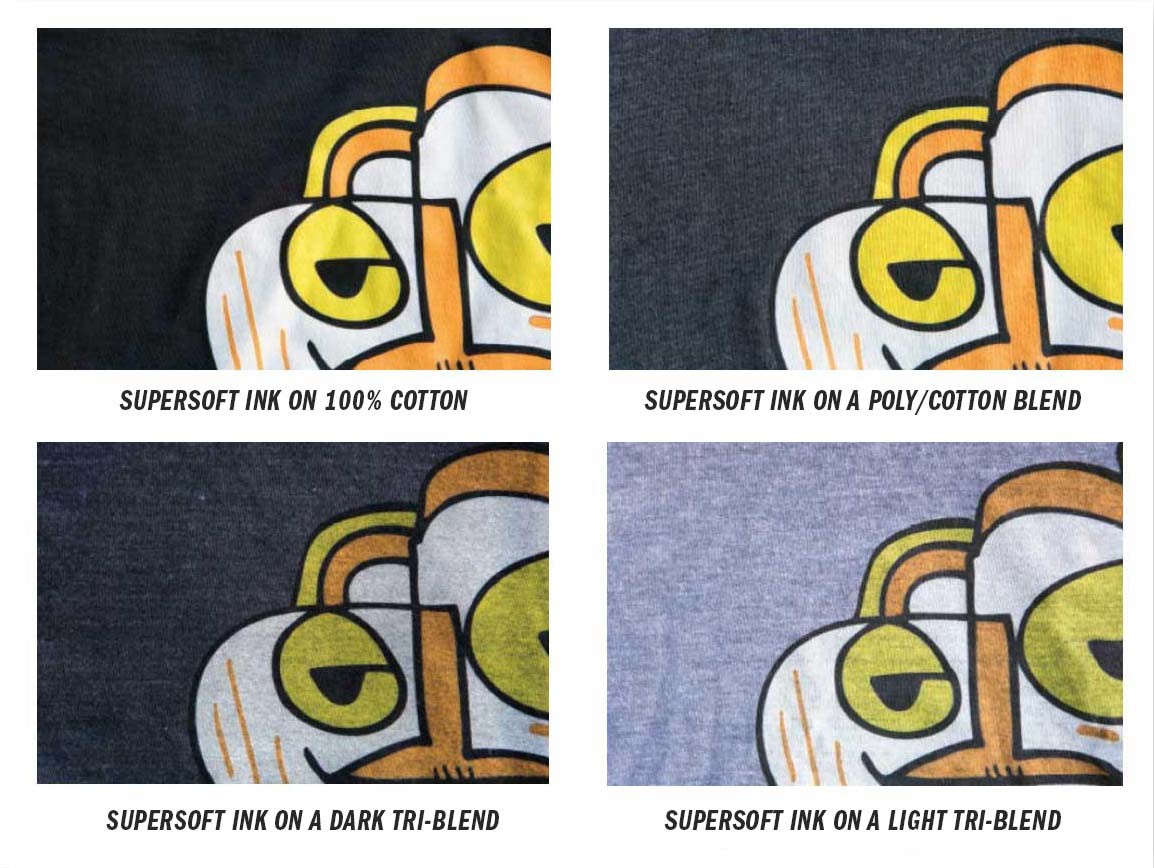

Tri-blend fabrics work exceptionally well for screen printing and other customization techniques. Their smooth texture allows for crisp, vibrant prints, making them a favorite among brands offering custom apparel.

Common Applications of Tri-Blend Fabrics

Clothing merchants often use tri-blend fabrics in products such as:

· T-Shirts: Soft, breathable, and stylish, tri-blend T-shirts are a staple in casual and athletic wear.

· Hoodies: Adding tri-blend fabrics to hoodies gives them a softer texture and a trendy aesthetic.

· Activewear: The stretch and durability of tri-blends make them a practical choice for gym wear and yoga outfits.

· Fashion-forward apparel: Tri-blend dresses and tops drape beautifully, making them a hit in high-end and boutique markets.

Pros and Cons of Tri-Blend Fabrics

Advantages:

· Soft and lightweight

· Wrinkle-resistant

· Highly durable

· Versatile for different garments and customization

· Premium, high-end look and feel

Disadvantages:

· Slightly more expensive than single-fiber fabrics

· May pill over time if not cared for properly

· Can be tricky to maintain (avoid high heat in washing/drying)

How Can Clothing Merchants Use Tri-Blend Fabrics Effectively?

1. Highlight the Comfort Factor:

Use tri-blend fabrics in products where comfort is key, such as loungewear, casual tops, or summer collections.

2. Focus on Durability for Activewear:

Market tri-blend garments as long-lasting options, emphasizing their resistance to shrinking and fading.

3. Customize for Branding:

Capitalize on the smooth texture of tri-blends for custom-printed merchandise. It’s a great way to create personalized T-shirts for corporate events or fashion lines.

4. Use for Premium Product Lines:

Leverage the premium drape and finish of tri-blends to create upscale collections, such as chic casual wear or eco-friendly fashion.

Best Printing Methods and Effects for Tri-Blend T-Shirts

1. Screen Printing

Why It Works:

Screen printing is a traditional method that works well with tri-blends, provided the right ink is used. Water-based and discharge inks are particularly effective for achieving a soft, breathable print that complements the smooth texture of tri-blends.

Pros:

Produces vibrant colors

Can create fine details and bold designs

Suitable for large production runs

Challenges:

· Requires skill to work with the rayon/polyester blend, as these fibers can resist traditional plastisol inks.

· May require additional curing to avoid scorching rayon.

2. Heat Transfer Vinyl (HTV)

Why It Works:

HTV uses heat and pressure to apply vinyl designs to garments. It works well for tri-blends but is best suited for small designs or lettering.

Pros:

· Durable and long-lasting if applied correctly

· Versatile for different design types

Challenges:

· Vinyl can feel heavier than the fabric, which might detract from the softness of a tri-blend T-shirt.

· Excessive heat during application can scorch rayon fibers.

3. Direct-to-Garment (DTG) Printing

Why It Works:

DTG printing involves digitally applying ink directly to the fabric, making it ideal for tri-blend T-shirts due to their smooth surface.

Pros:

· Excellent for detailed, multicolor designs

· No setup fees, making it cost-effective for small batches or one-off designs

· Water-based inks provide a soft finish that blends seamlessly with the fabric

Challenges:

· Tri-blends can be slightly tricky for DTG since the rayon and polyester components may affect ink absorption.

· Works best with pre-treated garments to enhance ink adherence.

4. Sublimation Printing

Why It Works:

Sublimation is a method that uses heat to transfer dye into polyester fibers, making it suitable for tri-blends with a higher polyester ratio.

Pros:

· Creates a vibrant, permanent design that won’t fade or peel

· Retains the fabric’s softness and stretch

· Best for all-over or edge-to-edge designs

Challenges:

· Limited to light-colored or white shirts (the dye doesn’t show well on dark fabrics).

· Requires a high polyester content, so results may not be as vibrant on tri-blends with a higher cotton or rayon percentage.

Key Considerations for Printing on Tri-Blend Fabrics

1. Fabric Sensitivity:

Rayon and polyester components make tri-blends sensitive to high heat and harsh treatment. Always test print on a sample before mass production to ensure compatibility.

2. Ink Selection:

Use water-based, discharge, or hybrid inks to achieve soft prints that complement the tri-blend’s texture. Avoid heavy ink layers that can stiffen the fabric.

3. Pretreatment:

For methods like DTG, pre-treat the fabric to improve ink absorption and color vibrancy.

4. Curing Temperature:

Keep curing temperatures below 320°F (160°C) to prevent damage to rayon fibers and reduce the risk of scorching.

Care Instructions for Tri-Blend Fabrics

To extend the life of tri-blend garments, advise your customers to:

· Wash in cold water to prevent damage to rayon and reduce fading.

· Avoid high heat when drying to preserve the fabric's integrity. Air drying is ideal.

· Handle gently to minimize pilling, especially in areas prone to friction.

Final Thoughts

As our journey into the world of Tri-Blend T-shirts ends, it’s clear that this trend is more than just a passing fad; it’s a style revolution. The fusion of comfort, durability, and a touch of sophistication has made Tri-Blend tees the go-to choice for the fashion-forward.

Ready to elevate your wardrobe with this contemporary trend? Whether you’re a fashion enthusiast or a business looking to make a statement, Tri-Blend T-shirts are the way to go.

For more inquiries or to purchase, don’t hesitate to contact us. Embrace the trend, redefine your style, and make a lasting impression with Tri-Blend T-shirts. Your journey to fashion innovation starts here. Contact us now!